The latest report on "Raw Sugar Production Cost Processes with Cost Analysis" provides an in-depth examination of the production cost structures, procurement resources, and market dynamics influencing the raw sugar industry. This detailed analysis is essential for industry stakeholders aiming to optimize their production processes, reduce costs, and stay competitive in the evolving market landscape.

Request For Free Sample: https://www.procurementresource.com/production-cost-report-store/raw-sugar/request-sample

Procurement Resource Assessment of Raw Sugar Production Process

The procurement resource assessment in the raw sugar production process is a critical element that influences overall production efficiency and cost-effectiveness. This assessment entails a thorough analysis of the resources required, from raw materials to labor and energy, to convert sugarcane or sugar beet into raw sugar.

The process begins with the cultivation and harvesting of sugarcane or sugar beet. Sugarcane is typically grown in tropical and subtropical regions, while sugar beet thrives in temperate climates. The choice of raw material significantly impacts procurement strategies and costs. Once harvested, the sugarcane or sugar beet is transported to processing facilities, where it undergoes various stages of extraction and purification.

Our report evaluates the procurement of essential inputs such as:

Sugarcane/Sugar Beet: The quality and yield of sugarcane or sugar beet directly affect the quantity of raw sugar produced. Factors such as soil quality, climatic conditions, and agricultural practices play a pivotal role in determining the yield and, consequently, the procurement cost.

Labor: Skilled labor is required for the efficient operation of machinery and equipment involved in the extraction and purification processes. Labor costs vary based on regional wage rates and the scale of operations.

Energy: Energy is a significant cost component in raw sugar production, particularly in the milling, extraction, and refining stages. The report assesses energy consumption patterns and explores opportunities for cost savings through energy-efficient technologies and practices.

Water: Water is used extensively in the washing, extraction, and purification processes. The cost and availability of water resources are critical considerations in the procurement assessment.

Product Definition

Raw sugar is the unrefined sugar derived from sugarcane or sugar beet. It is characterized by its pale brown color and contains impurities such as molasses, which impart a distinct flavor and aroma. Raw sugar serves as the primary feedstock for refined sugar production and is also used directly in certain industrial applications.

The product's characteristics, such as sucrose content, moisture level, and impurity profile, are determined by the production process and the quality of the raw materials used. Understanding these attributes is crucial for producers aiming to meet specific market requirements and standards.

Market Drivers

Several market drivers are shaping the raw sugar industry, influencing both production costs and market dynamics:

Growing Demand for Sweeteners: The global demand for sweeteners, including raw sugar, is driven by the expanding food and beverage industry, especially in emerging markets. This demand surge is prompting producers to enhance their production capacities and efficiency.

Technological Advancements: Innovations in agricultural practices, extraction technologies, and energy-efficient processing methods are reducing production costs and improving yield efficiencies. These advancements enable producers to remain competitive in a cost-sensitive market.

Sustainability Initiatives: Increasing consumer awareness about sustainability and environmental impact is driving the adoption of eco-friendly practices in raw sugar production. Producers are investing in sustainable agriculture, waste reduction, and energy conservation to meet regulatory and consumer expectations.

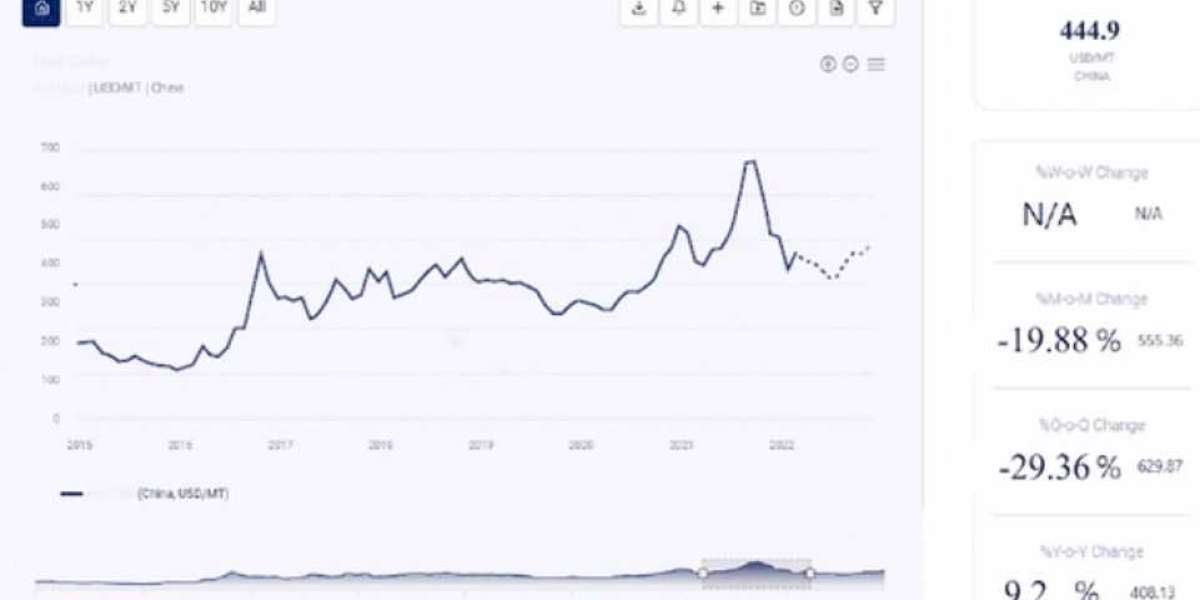

Price Volatility: The raw sugar market is subject to price fluctuations due to factors such as weather conditions, geopolitical events, and changes in trade policies. Understanding these market dynamics is essential for effective procurement and cost management strategies.

Raw Materials Requirements

The primary raw materials required for raw sugar production are:

Sugarcane/Sugar Beet: The quality, yield, and cost of these raw materials are influenced by agricultural practices, climatic conditions, and regional availability.

Water: Essential for various stages of the production process, including washing, extraction, and purification.

Energy: Required for operating machinery and equipment, particularly in the milling and refining stages.

Chemicals: Used in the clarification and purification processes to remove impurities and improve the quality of raw sugar.

Costs and Key Process Information

The cost analysis of raw sugar production encompasses several key components:

Cultivation and Harvesting: Costs associated with land preparation, planting, irrigation, fertilization, pest control, and harvesting of sugarcane or sugar beet.

Transportation: Expenses incurred in transporting raw materials from fields to processing facilities.

Processing: Costs related to milling, extraction, clarification, crystallization, and drying of raw sugar. This includes energy consumption, labor, maintenance, and depreciation of equipment.

Packaging and Storage: Expenses for packaging raw sugar for transportation and storage, including materials and logistics.

Quality Control: Costs associated with ensuring the raw sugar meets industry standards and specifications, including laboratory testing and quality assurance measures.

Looking for an Exhaustive and Personalized Report?

Our comprehensive and personalized report on raw sugar production cost analysis is designed to provide businesses with the insights they need to optimize their production processes, manage costs effectively, and enhance competitiveness. Whether you are a producer, supplier, or investor, our report offers valuable information to support your strategic decision-making.

Key features of our report include:

- Detailed cost analysis of each stage of raw sugar production.

- Procurement strategies and resource assessment.

- Market trends and drivers impacting the raw sugar industry.

- Comprehensive analysis of raw materials requirements and costs.

- Key process information and opportunities for cost savings.

- Tailored recommendations for improving production efficiency and sustainability.

Contact Us:

Company Name: Procurement Resource

Contact Person: Christeen Johnson

Email: sales@procurementresource.com

Toll-Free Number: USA Canada – Phone no: +1 307 363 1045 | UK – Phone no: +44 7537 132103 | Asia-Pacific (APAC) – Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA