Monel is a group of nickel alloys, primarily composed of nickel (up to 67%) and copper, with small amounts of iron, manganese, carbon, and silicon. Known for its excellent corrosion resistance and high strength, Monel is used in various industries, including marine, chemical, and aerospace. Understanding the Monel price trend is essential for manufacturers, suppliers, and market analysts. This article provides a comprehensive analysis of the factors influencing Monel prices, historical trends, recent developments, and future projections.

Factors Influencing Monel Prices

Raw Material Costs

- The primary components of Monel are nickel and copper. Fluctuations in the prices of these metals significantly impact the cost of producing Monel. Market dynamics, including supply and demand, geopolitical events, and mining activities, influence the prices of these raw materials.

Energy Costs

- The production of Monel involves energy-intensive processes such as smelting and alloying. Changes in energy prices, including those for electricity and natural gas, can affect overall production expenses and influence Monel prices.

Labor Costs

- Labor costs, including wages, benefits, and training, contribute to the overall cost of producing Monel. Variations in labor costs based on geographic location and labor market conditions can influence the final price of the alloy.

Production Technology

- Advances in production technology can improve efficiency and reduce costs. Conversely, outdated or inefficient production processes can increase expenses. Investments in modern, efficient production methods can help stabilize prices over time.

Transportation and Logistics

- Transportation costs for raw materials to the production plant and finished products to the market are significant factors in production costs. Proximity to raw material sources and target markets can influence transportation expenses and overall profitability.

Regulatory Compliance

- Compliance with environmental and safety regulations can add to production costs. Investments in pollution control, waste management, and workplace safety are necessary to meet regulatory standards, impacting the price of Monel.

Market Demand

- Demand for Monel in various industries, such as marine, chemical, and aerospace, can influence prices. Increased demand can drive prices up, while decreased demand can lead to lower prices.

Global Economic Conditions

- Economic conditions, including inflation, exchange rates, and economic growth, can influence the price of Monel. Economic downturns can reduce demand and lower prices, while economic growth can increase demand and drive prices up.

Supply Chain Dynamics

- The availability of raw materials, transportation issues, and other supply chain factors can affect the price of Monel. Disruptions in the supply chain, such as logistical bottlenecks or raw material shortages, can lead to price volatility.

Enquire For Regular Prices: https://www.procurementresource.com/resource-center/monel-price-trends/pricerequest

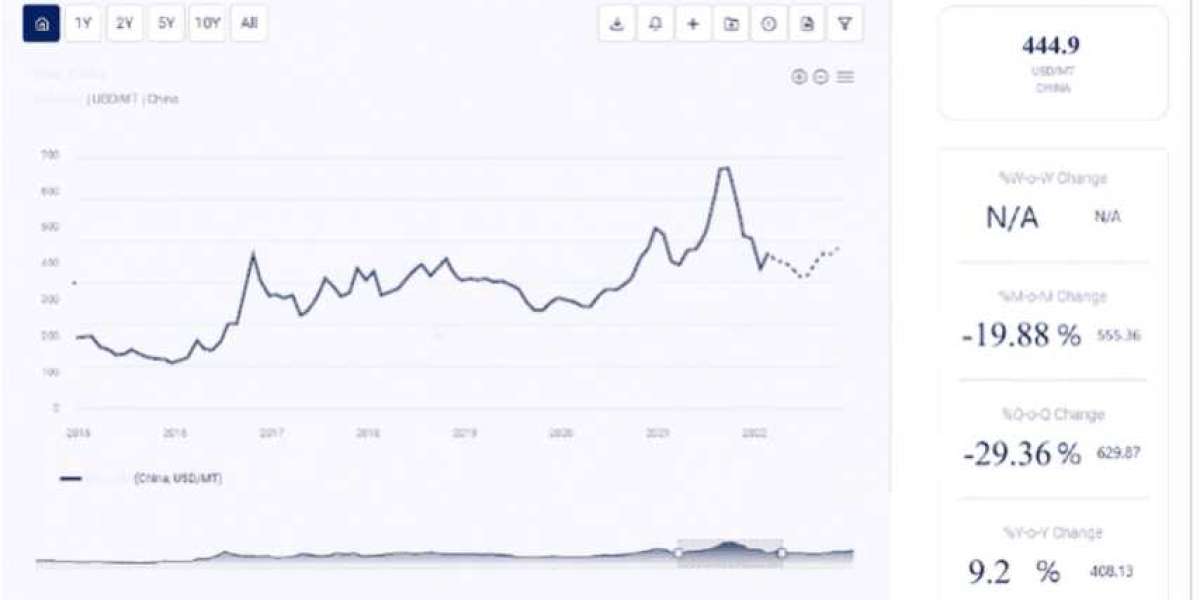

Historical Trends

Analyzing historical trends in Monel prices provides valuable insights into the industry's evolution and helps predict future patterns.

Early Development

- In the early stages of Monel production, prices were relatively high due to limited production capacity and technology. The use of Monel was primarily confined to specialized applications, resulting in higher costs.

Industrialization and Mechanization

- The industrialization of Monel production in the 20th century brought significant changes. The adoption of advanced production technologies and improved raw material handling increased efficiency and reduced production costs.

Technological Advancements

- Technological innovations in the latter half of the 20th century, including more efficient smelting and alloying methods, contributed to a gradual reduction in Monel prices. These advancements made Monel more accessible for a broader range of applications.

Market Expansion

- The expansion of Monel applications in various industries led to increased production volumes and economies of scale. This expansion helped stabilize prices and made Monel more cost-competitive.

Regulatory Changes

- Changes in environmental and safety regulations have influenced Monel prices over time. Stricter regulations have necessitated investments in compliance measures, impacting production costs and prices.

Recent Developments

In recent years, the Monel market has experienced notable trends driven by economic conditions, regulatory changes, and technological advancements.

Sustainability Initiatives

- There is a growing emphasis on sustainability and reducing the environmental impact of metal production. Companies are investing in greener production methods and sustainable practices, which can influence production costs and prices.

Rising Raw Material Costs

- The prices of key raw materials used in Monel production, such as nickel and copper, have been rising due to supply chain disruptions and increased demand. These rising raw material costs have directly impacted the price of Monel.

Technological Innovations

- Advances in production technology, including more efficient smelting and alloying methods, have helped mitigate some cost increases. These innovations have improved production efficiency and reduced waste, contributing to price stability.

Regulatory Compliance

- Compliance with increasingly stringent environmental and safety regulations continues to impact production costs. Investments in pollution control, waste management, and workplace safety are necessary to meet regulatory standards, affecting Monel prices.

Market Demand

- Demand for Monel remains strong, particularly in the marine, chemical, and aerospace industries. The ongoing need for corrosion-resistant and high-strength materials has sustained demand and influenced prices.

Case Study: Monel Prices in 2023

In 2023, the Monel market faced a dynamic landscape shaped by economic recovery, regulatory changes, and technological advancements. Here’s a closer look at the key developments affecting prices:

Economic Recovery and Increased Demand

- As global economies rebounded from the COVID-19 pandemic, industrial and manufacturing activities increased, driving higher demand for Monel. This surge in demand influenced raw material prices and production costs, impacting Monel prices.

Rising Raw Material Costs

- Prices of key raw materials, such as nickel and copper, continued to rise due to supply chain disruptions and increased demand. These rising raw material costs directly impacted the price of Monel.

Technological Innovations

- Advances in production technology, including process optimization and energy-efficient methods, helped improve production efficiency and reduce costs. These innovations contributed to price stability despite rising raw material costs.

Regulatory Compliance

- Ongoing regulatory changes, particularly in environmental and safety standards, necessitated investments in compliance measures. These investments impacted production costs and influenced Monel prices.

Sustainability Initiatives

- Investments in sustainability initiatives, such as greener production methods and waste reduction, continued to grow. While these initiatives aim to reduce long-term costs and environmental impact, they require initial investment and ongoing management.

Future Projections

The future of Monel prices will be shaped by a complex interplay of technological advancements, sustainability initiatives, market dynamics, and regulatory developments. Here are some key projections for the Monel market:

Technological Advancements

- Continued research and development in production technology, including more efficient smelting and alloying methods, are expected to further optimize Monel production. These innovations will enhance productivity, reduce costs, and improve environmental performance.

Sustainability and Environmental Compliance

- The shift towards sustainability and environmental compliance will continue to grow, driven by regulatory requirements and market demand for greener products. Investments in sustainable production methods and waste reduction will impact production costs and market competitiveness.

Raw Material Costs

- The prices of key raw materials, such as nickel and copper, will continue to influence Monel prices. Supply chain dynamics, geopolitical factors, and market demand will impact raw material costs and overall production expenses.

Market Demand

- Global demand for Monel is expected to remain strong, particularly in the marine, chemical, and aerospace industries. Market dynamics, including trade policies, economic conditions, and public health concerns, will influence prices and profitability.

Regulatory Developments

- Government policies and regulations, particularly those related to environmental protection and safety standards, will play a crucial role in shaping Monel prices. Compliance with these regulations will require ongoing investments in pollution control, waste management, and workplace safety.

Conclusion

The price of Monel is influenced by a myriad of factors, including raw material costs, energy costs, labor costs, production technology, regulatory compliance, market demand, supply chain dynamics, and global economic conditions. Understanding these factors and their interplay is essential for stakeholders in the metal industry to navigate the complex landscape of Monel production.

In recent years, the Monel market has experienced significant developments driven by sustainability initiatives, rising raw material costs, technological advancements, and regulatory changes. Looking ahead, the future of Monel prices will be shaped by ongoing technological innovations, sustainability and environmental compliance efforts, raw material costs, market demand, and regulatory developments.

As the world transitions towards a more sustainable and resilient metal industry, the Monel market is poised for exciting developments. Staying informed about these trends and their implications will be crucial for stakeholders across various industries to make informed decisions and capitalize on emerging opportunities in the ever-evolving Monel market.